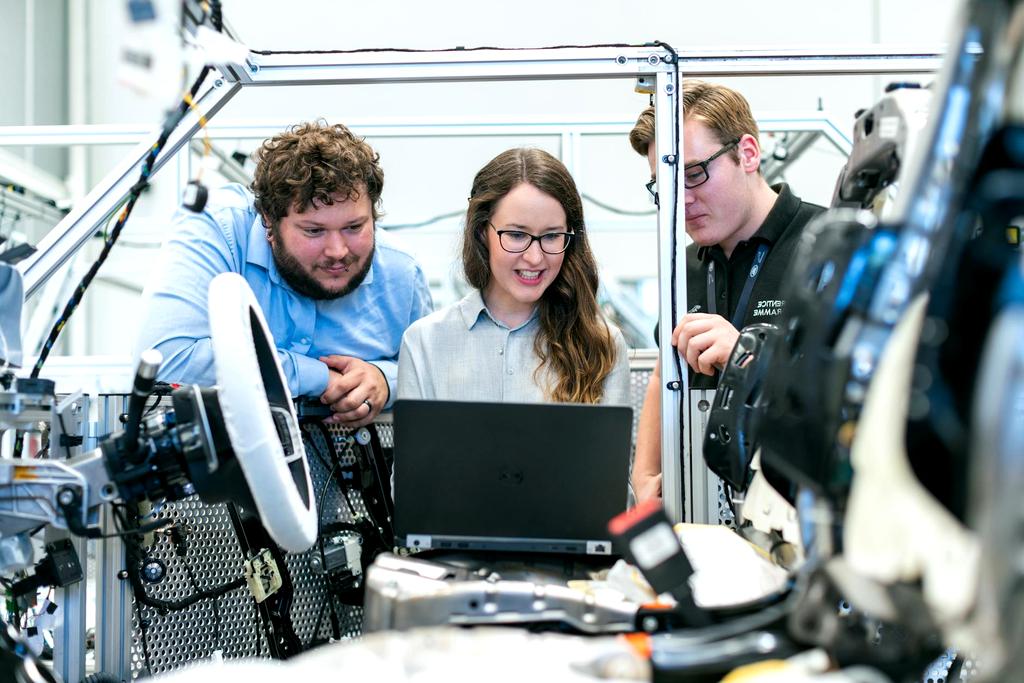

Revolutionary AI-Driven Process Automation

Transform your industrial operations with cutting-edge AI technology that optimizes workflows, reduces costs, and drives unprecedented efficiency gains.

Transform your industrial operations with cutting-edge AI technology that optimizes workflows, reduces costs, and drives unprecedented efficiency gains.

Our AI-driven platform delivers comprehensive solutions that revolutionize industrial processes through smart automation.

Advanced algorithms that learn from your production data to continuously improve processes and predict maintenance needs.

Monitor every aspect of your industrial operations in real-time with intelligent dashboards and anomaly detection.

Forecast production trends, identify bottlenecks, and optimize resource allocation with AI-powered analytics.

Create intelligent workflows that automate complex industrial processes with minimal human intervention.

Enterprise-grade security protocols protect your operational data while enabling digital transformation.

Connect with existing systems and industrial equipment through our extensive API ecosystem and connectors.

Error Reduction

Cost Savings

Productivity Boost

Global Deployments

Our AI-driven automation solutions provide tangible benefits that create immediate value and long-term competitive advantage.

Streamline complex processes and eliminate inefficiencies through intelligent automation.

Predictive maintenance algorithms identify potential failures before they occur, minimizing costly downtime.

Our platform grows with your business, from single production line optimization to enterprise-wide deployment.

Reduce waste, energy consumption, and carbon footprint through optimized processes and resource utilization.

Discover how leading companies across diverse industries have transformed their operations with our AI automation solutions.

Implemented AI-driven quality control that reduced defects by 92% and increased production throughput by 37%.

Read Case Study

Automated compliance monitoring and batch processing resulting in 63% faster production cycles and zero compliance violations.

Read Case Study

Deployed predictive maintenance system across 27 power plants, reducing unplanned outages by 78% and maintenance costs by 41%.

Read Case StudyA seamless, four-step process to transform your industrial operations with cutting-edge AI technology.

We analyze your current processes, identify bottlenecks, and create a customized automation roadmap.

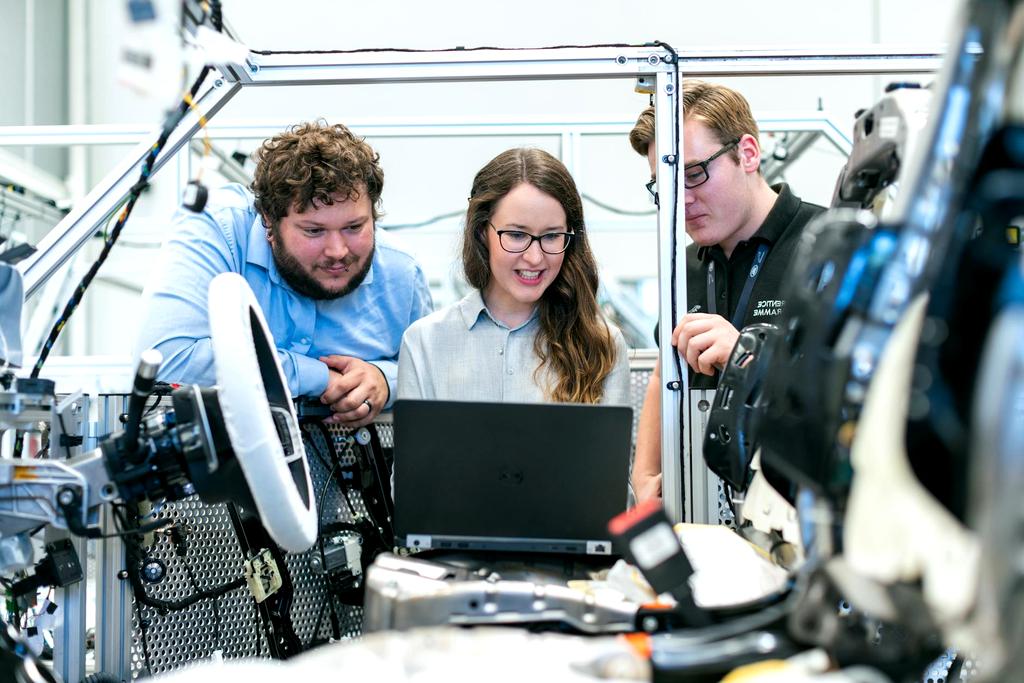

Our engineers deploy AI solutions tailored to your specific industrial environment and requirements.

Machine learning algorithms continuously improve performance based on real-world operational data.

Ongoing support and updates ensure your automation solution evolves with your business needs.

Hear from executives who have transformed their operations with our AI automation platform.

CTO, TechFab Industries

"Implementing this AI automation platform has been transformative for our manufacturing processes. We've seen a 43% reduction in operational costs and significant quality improvements across all production lines."

Operations Director, GreenEnergy

"The predictive maintenance capabilities alone have saved us millions in prevented downtime. The platform's ability to learn and adapt to our specific energy production challenges has been remarkable."

VP of Innovation, PharmaNext

"In the highly regulated pharmaceutical industry, the combination of automation and compliance monitoring has been invaluable. We've accelerated production while maintaining perfect regulatory compliance."

Get answers to common questions about our AI-driven process automation solutions.

Join hundreds of forward-thinking companies leveraging AI to achieve operational excellence.

Schedule a ConsultationComplete the form below to schedule a personalized demonstration and discuss your specific automation needs.

Subscribe to our newsletter to receive the latest insights, case studies, and innovations in industrial automation.